Brand: Woer Type: SBRS - (3X)G Material: ⑴ EVA ; ⑵ Hot-melt adhesive/thick Glue State: Soft pipe Shape: Pipe Color: Black (Other color available upon request) Shrink Ratio: 3:1 Longitudinal Shrink Ratio: ≤±8% Smell: No Operation temperature: -45℃~25℃ Rated Voltage: 600V Shrink temperature: 125℃~200℃ Decompose temperature: 125℃ shrink, but don’t decompose Flash point: Fire-resistant Natural temperature: Normal temperature Explode rate: No Environment: RoHS Compliant We also supply this series thick Glue convoluted tubing with different specifications:

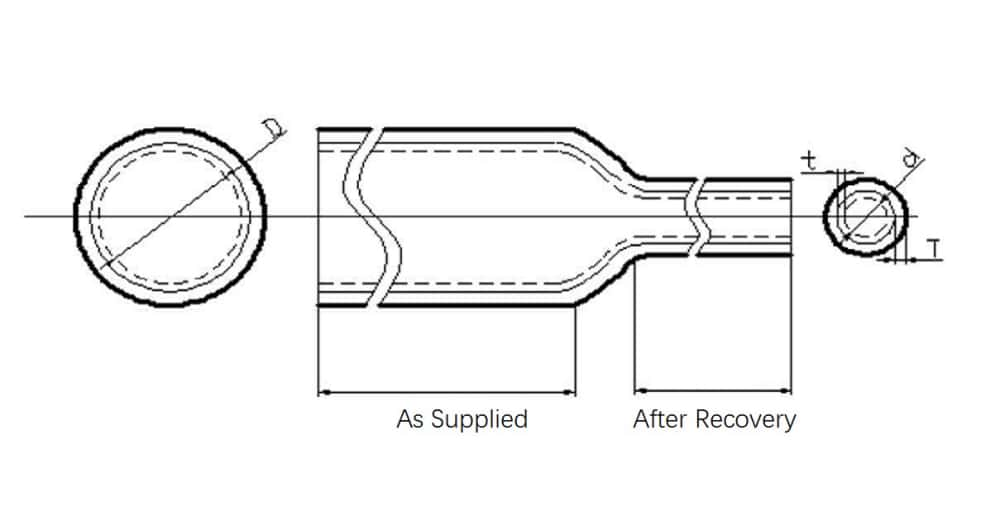

Brand: Woer Type: SBRS - (3X)G Material: ⑴ EVA ; ⑵ Hot-melt adhesive/thick Glue State: Soft pipe Shape: Pipe Color: Black (Other color available upon request) Shrink Ratio: 3:1 Longitudinal Shrink Ratio: ≤±8% Smell: No Operation temperature: -45℃~25℃ Rated Voltage: 600V Shrink temperature: 125℃~200℃ Decompose temperature: 125℃ shrink, but don’t decompose Flash point: Fire-resistant Natural temperature: Normal temperature Explode rate: No Environment: RoHS Compliant We also supply this series thick Glue convoluted tubing with different specifications: | Parts No. | Reference No. | As Supplied Min I D Ø (mm) | After Recovery Max I.d Ø (mm) |

| RSGG-T-3.2mm | RSGG-T-3.2mm | ≥3.2 | ≤1.00 |

| RSGG-T-4.8mm | RSGG-T-4.8mm | ≥4.8 | ≤1.60 |

| RSGG-T-6.4mm | RSGG-T-6.4mm | ≥6.4 | ≤2.20 |

| RSGG-T-7.9mm | RSGG-T-7.9mm | ≥7.9 | ≤2.70 |

| RSGG-T-9.5mm | RSGG-T-9.5mm | ≥9.5 | ≤3.20 |

The ordinary heat shrinkable pipe is also called single wall tubing, and the heat shrinkable tubing with hot-melt adhesive is called double wall tubing.

The ordinary heat shrinkable pipe is also called single wall tubing, and the heat shrinkable tubing with hot-melt adhesive is called double wall tubing. | Raw material | Molecular formula | Application | Content |

| Ethylene-vinylacetate copolymer | (CH2CH2) m-(CH2-CH-COOCH3)n | Main components | 50% |

| Magnesium Hydroxide | Mg(OH)2 | Flame retardant | 30% |

| Phosphorus | P | Flame retardant | 10% |

| Anti-oxide | C35H62O3 | Antioxidant | 1% |

| pigment | ----- | Colorant | 4% |

| Hot melt adhesive | ----- | Sealing material | 5% |

| INK | ----- | Printing material | ----- |

| PROPERTY | TEST METHOD | STANTARD |

| Tensile Strength(MPa) | ASTM D2671 | ≥10.4 |

| Elongation(%) | ASTM D2671 | ≥200 |

| Tensile Strength after aging(MPa) | UL224 158℃×168h | ≥7.3 |

| Elongation at Break after aging(%) | UL224 158℃×168h | ≥100 |

| Dielectric strength(kv/mm) | IEC 60243 | ≥15 |

| Volume resistance(Ω.cm) | IEC 60093 | ≥1×1014 |

| Hot Melting Adhesive Property | ||

| PROPERTY | TEST METHOD | Standard |

| Water Absorption | ASTM-D570 | <0.2% |

| Vicat Softening Point | ASTM-E28 | 95℃ |

| Peel Strength(PE) | ASTM-D1000 | 120N/25mm |

| Peel Strength(AL) | ASTM-D1000 | 80N/25mm |